Our Value

An ultrathin layer sealed within a laminated glass structure

Perovskite photovoltaics generate electricity through an ultrathin layer (approx. 0.5 μm) formed from liquid material.

However, this layer is prone to degradation when exposed to external air, making it challenging to secure the long-term durability required for architectural applications.

Panasonic Holdings Corporation employs a laminated glass structure in which a perovskite layer is formed directly on glass that meets building-standard strength and thickness requirements, then sealed by adding another layer of glass on top.

By combining durability-enhancing material technologies with glass-sealing techniques, we enable integration into building materials while ensuring high reliability. This approach aims to maintain photovoltaic functionality while securing the long-term durability needed for the product to be used directly as architectural glass.

Large-area coating technology for forming ultrathin layers on architectural glass

Glass used in building materials varies in size by the millimeter to suit each building, and it also comes in a wide range of thicknesses and specifications.

High-precision coating technology is essential to form a uniform, ultrathin photovoltaic layer on the surface of such diverse types of glass.

Panasonic Holdings Corporation has developed an original large-area coating technique for architectural glass by applying its industrial inkjet technology developed through the production of OLED displays. This technology contributes to enhancing the performance and reliability of the glass-based perovskite photovoltaics.

Note: The illustration shows an inkjet device used to apply photovoltaic materials on architectural glass.

Heat-shielding effect expected from power generation

The glass-based perovskite photovoltaics is expected to provide a heat-shielding effect by converting part of incoming sunlight into electricity, thereby reducing the amount of thermal energy entering a room.

This heat-shielding effect can help lower air-conditional loads and potentially enhance the overall energy-saving performance of a building. Such benefits are particularly promising for regions with high solar radiation or buildings with large glass surfaces.

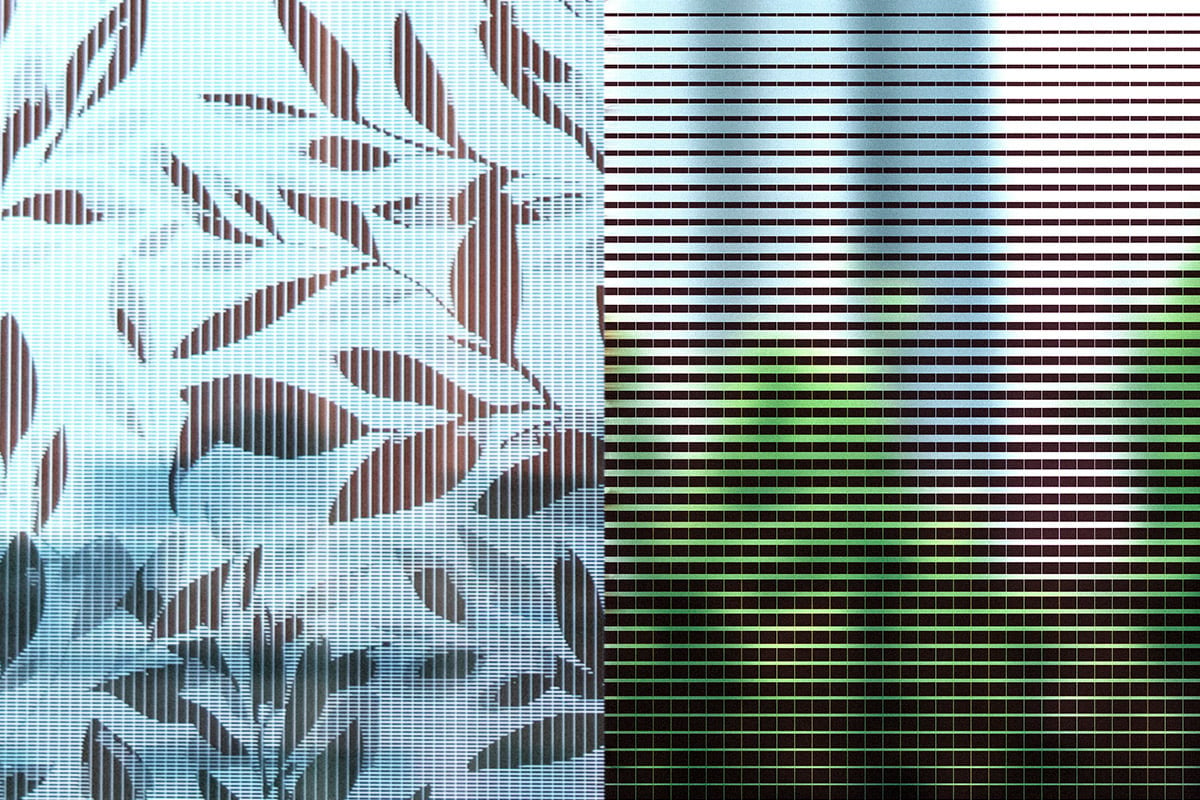

Customizable size, glass thickness, transparency, and graphic patterns

Glass size, thickness, transparency, and graphic patterns can be customized to suit the installation environment and architectural design.

This enables us to comply with a wide range of design requirements, from simple transparent patterns that blend naturally into a space to decorative patterns that highlight architectural and interior design.

By combining our proprietary material technologies with inkjet coating and laser processing techniques, we aim to offer flexible design adaptability.

Transforming windows and walls that once produced zero electricity into power-generating surfaces

One of the key values of building-integrated photovoltaics is that they can be incorporated into architecture as part of the building materials themselves.

Windows, walls, balconies, and other elements of buildings previously unrelated to power generation can now become sources of electricity.

We believe this represents significant potential to turn spaces that once produced no energy into areas that actively generate power.

Among the leading level of photovoltaic performance

The perovskite photovoltaic module under development by Panasonic Holdings Corporation has achieved a leading level of conversion efficiency among practical-size modules. (18.1% conversion efficiency with an 804-cm2 perovskite module, certified by a third-party testing organization)

This level of conversion efficiency value is comparable to that of widely adopted crystalline silicon photovoltaics.

Low-environmental-impact manufacturing process

Conventional crystalline silicon photovoltaics require temperatures exceeding 1,000°C to produce high-purity silicon, consuming a large amount of energy during manufacturing. In contrast, perovskite photovoltaics can be produced at much lower temperatures (between 100 to 200°C), significantly reducing energy consumption.

Furthermore, when comparing the time needed for the generated electricity to offset the energy consumed during manufacturing, certain estimates suggest that crystalline silicon photovoltaics require approximately two to three years, whereas perovskite photovoltaics can recover this energy in just three to four months.* This makes perovskite photovoltaics highly promising from a sustainability standpoint, offering excellent energy efficiency during the manufacturing process.

*Source : T. Ibn-Mohammed et al., Renew. Sustain. Ener. Rev., 80 (2017) pp. 1321-1344